Exhaust Gas (WHRB, Recuperator, etc)

Exhaust Gas Solutions: WHRB, Recuperators, Etc.

At Komten Hareev, we specialize in advanced exhaust gas recovery systems that optimize thermal efficiency and reduce fuel consumption across industrial operations. Our solutions—including Waste Heat Recovery Boilers (WHRBs), Recuperators, and custom-designed systems—help industries turn waste heat into valuable energy.

Overview of Exhaust Gas Recovery Systems

Exhaust gas systems capture and reuse thermal energy that would otherwise be lost through flue gases. By integrating heat recovery units into your process, you can significantly lower operational costs and environmental impact.

Overview of Exhaust Gas Recovery Systems

Exhaust gas systems capture and reuse thermal energy that would otherwise be lost through flue gases. By integrating heat recovery units into your process, you can significantly lower operational costs and environmental impact.

Types of Systems

- Waste Heat Recovery Boilers (WHRB)

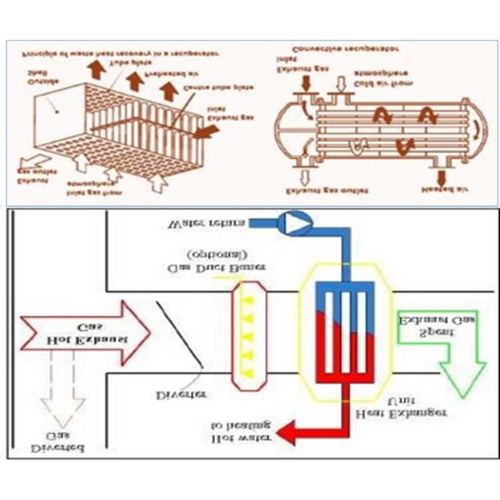

WHRBs capture heat from exhaust gases to generate steam or hot water, reducing the need for additional fuel sources in industrial heating or power generation. - Recuperators

These are heat exchangers that transfer heat from hot exhaust gases to incoming combustion air, improving burner efficiency and reducing emissions. - Economizers & Heat Exchangers

Used for preheating feedwater or process fluids using waste heat, enhancing system efficiency. - Custom Exhaust Heat Recovery Units

Engineered solutions tailored to meet specific process requirements, fuel types, and space constraints.

Key Benefits

- Energy Savings: Reduce fuel consumption by utilizing recovered heat.

- Emission Reduction: Minimize greenhouse gas output and support sustainability goals.

- Improved Efficiency: Enhance boiler and process performance.

- Cost Reduction: Lower energy bills and increase return on investment.

- Compact & Scalable Designs: Custom-built systems that fit seamlessly into your existing infrastructure.

Applications Across Industries

- Cement & Steel Plants

Recovering heat from kilns, furnaces, and flue gases. - Power Generation

Enhancing turbine and engine efficiency through heat reuse. - Petrochemical & Refinery Units

Preheating and process steam generation. - Textile & Paper Industries

Improving drying systems and boiler feedwater preheating.

Challenges

- Corrosive Flue Gases: Requires materials resistant to chemical attack.

- System Integration: Needs careful design to match existing equipment.

- Heat Quality Variation: Efficiency depends on exhaust gas temperature and flow stability.

- Maintenance Needs: Regular cleaning and monitoring are crucial for optimal performance.

Conclusion

Exhaust gas heat recovery is a smart, sustainable approach to energy management. At Komten Hareev, our exhaust recovery systems are engineered for performance, longevity, and environmental responsibility. Whether you need a standard WHRB or a fully customized recuperative solution, we bring you reliable technologies to maximize your energy efficiency and reduce operational costs.