Automation & Smart Factory

At Komten Hareev, we empower industries to transition into the Factory of the Future with intelligent automation and smart factory solutions. By integrating advanced technologies like IoT, AI, and real-time data analytics, we help businesses boost productivity, reduce waste, and make faster, smarter decisions across every level of operation.

What is a Smart Factory?

A Smart Factory is a fully connected, flexible, and data-driven production environment where machines, systems, and humans work together seamlessly. Enabled by industrial automation, sensor networks, and cloud platforms, smart factories adapt in real time to changing conditions—maximizing efficiency and minimizing downtime.

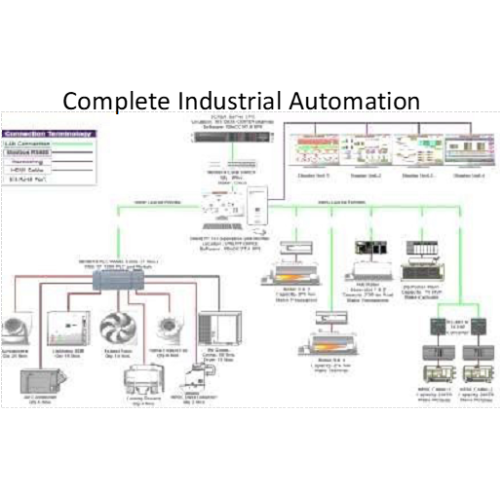

Our Automation Capabilities

- Process Automation

PLC & SCADA-based systems for seamless machine control and monitoring. - Robotics Integration

Deployment of robotic arms, conveyors, and AGVs for repetitive tasks and material handling. - IoT & Sensor Networks

Real-time data capture from machines, utilities, and environmental sensors. - Energy Management Automation

Smart control systems for compressors, HVAC, chillers, and lighting to optimize energy usage. - Predictive Maintenance

AI-driven insights to prevent breakdowns before they happen. - Digital Twins & Simulation

Virtual models of your plant to test changes, plan expansions, and optimize workflows.

Industry Applications

Industrial compressors are essential in numerous industries, including:

- Manufacturing: Powering tools, equipment, and assembly lines.

- Oil & Gas: Gas compression, pipeline transport, and drilling operations.

- Automotive: Paint spraying, air tools, and assembly processes.

- Pharmaceuticals: Sterile air supply and material handling.

- Chemical Processing: Gas handling and pressure regulation in sensitive processes.

Benefits of Smart Factory Implementation

- Increased Efficiency

Automated processes reduce human error, speed up production, and lower cycle times. - Data-Driven Decisions

Access to real-time data for better planning, forecasting, and optimization. - Reduced Downtime

Proactive monitoring and predictive maintenance keep machines running smoothly. - Improved Quality Control

Instant feedback and error detection at every stage of production. - Energy & Cost Savings

Automated controls ensure optimal resource usage and reduced operational waste. - Scalability & Flexibility

Modular systems that grow with your business and adapt to new products or processes.

Industry Applications

- Automotive Manufacturing

Robotic assembly, quality inspection, and traceability systems. - Pharmaceuticals & Chemicals

Batch process automation, regulatory compliance, and sterile environment control. - Textile & Garment

Automated fabric handling, cutting, and dyeing operations. - Food & Beverage

Smart packaging lines, cold chain monitoring, and process automation. - Electronics & Semiconductor

Precision handling, cleanroom monitoring, and production traceability.

Conclusion

Automation and Smart Factory technologies are no longer optional—they’re essential for staying competitive in a digital-first world. At Komten Hareev, we bring the expertise, technology, and integration capabilities to help you transform your operations into a connected, intelligent, and future-ready ecosystem. Step into Industry 4.0 with confidence.